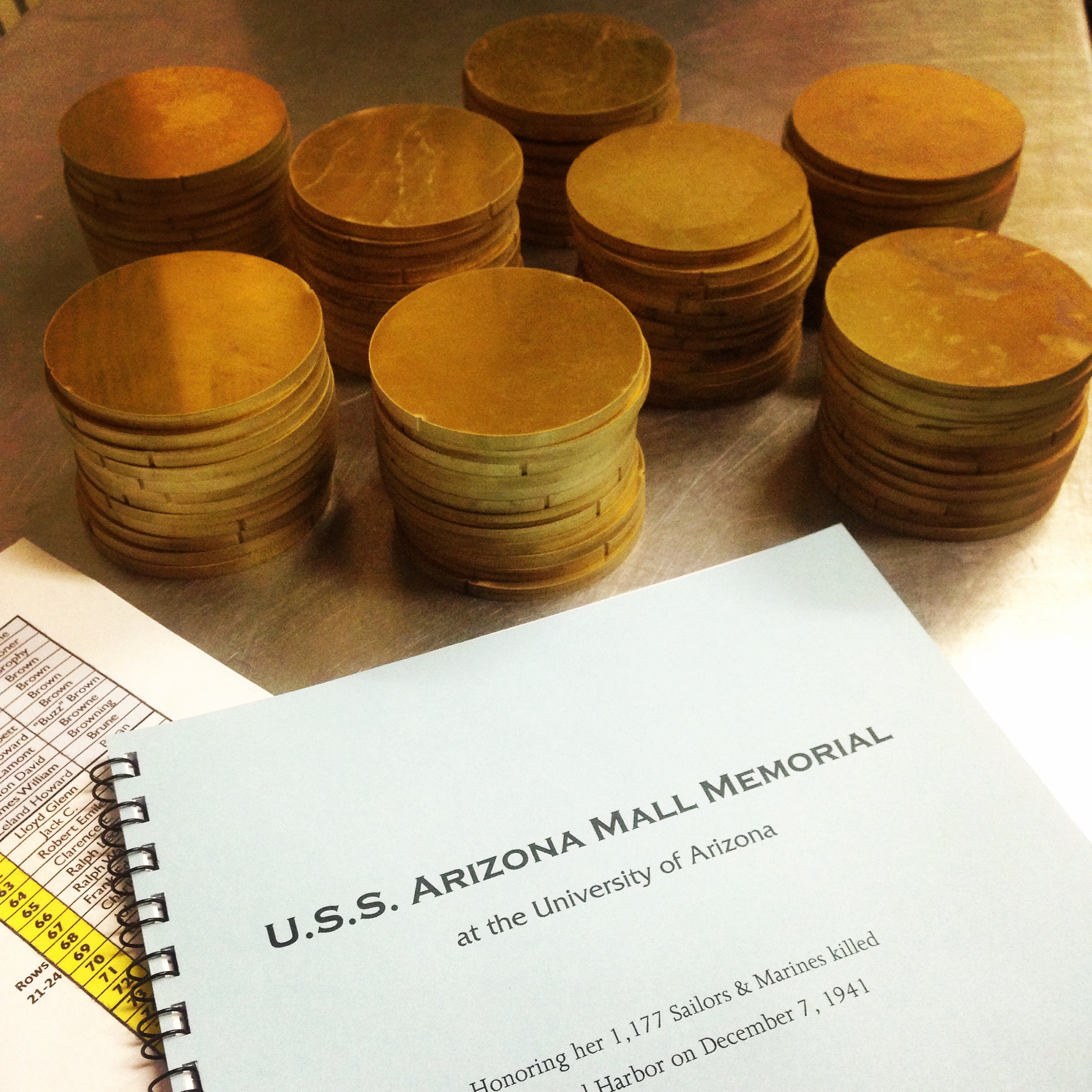

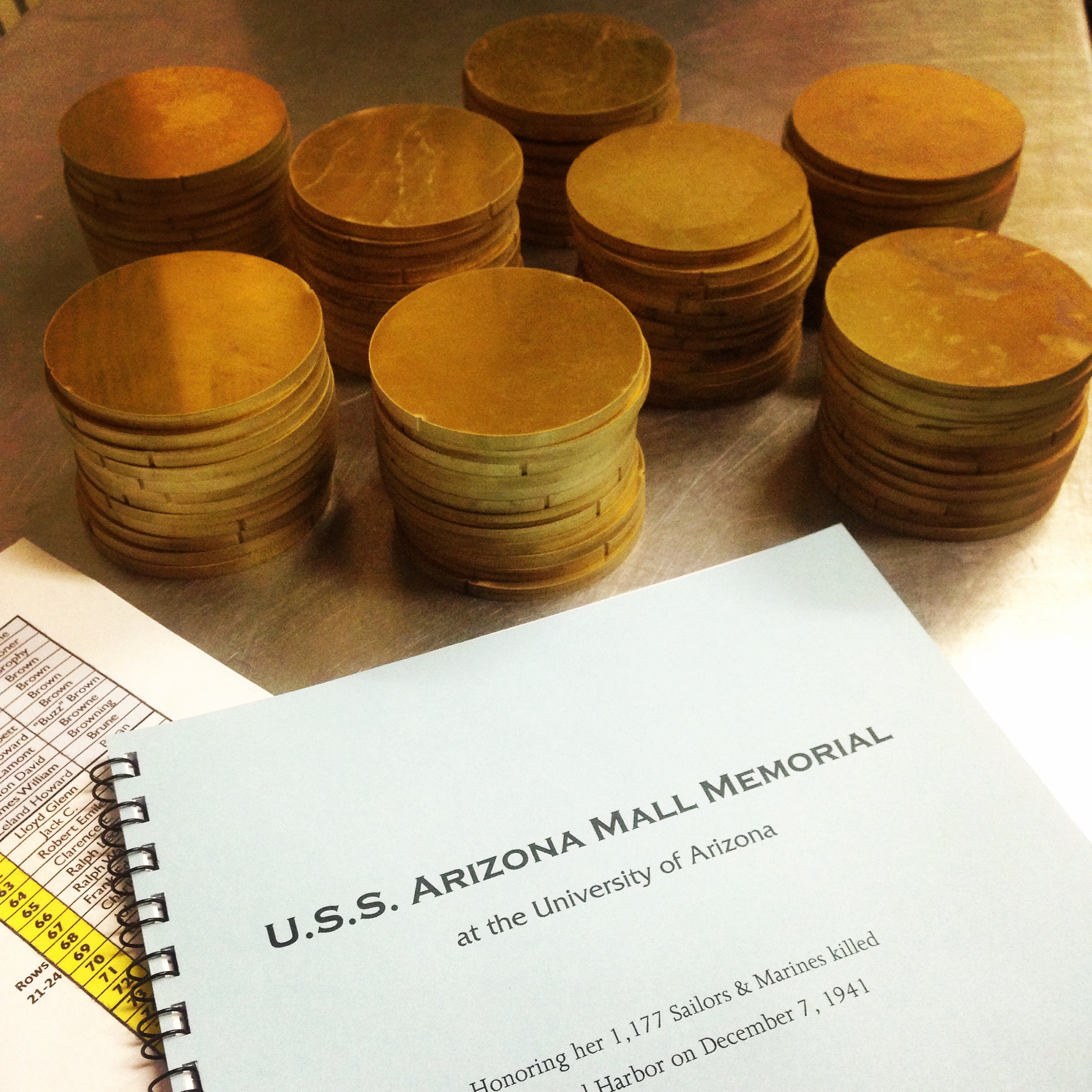

Uss Arizona Mall Memorial Case Study

The USS Arizona Mall Memorial is a commemorative installation located on the University of Arizona campus in Tucson.

Handling high-volume production with tight turnaround requirements

Engraving a wide variety of materials and complex geometries, including:

Ensuring accurate logo placement, repeatable consistency, and support for serialized markings across hundreds of unique part types

Many of the components also demanded custom handling due to surface finish or cylindrical/contoured designs.

To meet these demands, LEO Engraving:

Over 4,000 components engraved monthly

Materials include:

Engraving tasks:

“In 2025 GG&G Inc. celebrated its 31st year in business. LEO Armory (now LEO Engraving) has been engraving GG&G products with the company logo and/or name for about a third of that time. In doing a quick calculation, that amounts to about 1,000,000 GG&G parts being engraved by LEO Armory/LEO Engraving. Were there a few mistakes? Yep, but very, very, very, and let me add very few mistakes. When they happened, Jeff, the owner of LEO and his great staff, always stood tall and accepted the responsibility and made it right! They did whatever it took to make it right. The staff at LEO Engraving has treated our staff with respect, friendliness, and a willingness to meet our schedule. It is apparent that Jeff and the fine team at LEO Engraving have not succumbed to the workplace disease called COMPLACENCY which has infected so many businesses across the United States! The core values at LEO Engraving are evident. They clearly include providing value through excellent workmanship, accountability and outstanding customer service.

I have one question for those of you reading this review and are considering employing LEO Engraving: “Why wouldn’t you want to employ the services of a company where the owner has created a culture of success that is of value to you the customer, with high quality engraving, excellent customer service, at a competitive price?”

These are the reasons GG&G employs the services of LEO Engraving and refers to their organization internally, not just as a vendor, but as a Vendor Partner.”

— Thomas A. Newhall, President, GG&G Inc.

Years of experience delivering intricate, custom designs

The USS Arizona Mall Memorial is a commemorative installation located on the University of Arizona campus in Tucson.

The Arizona Bowl is one of college football’s premier postseason games, delivering nationally televised excitement while spotlighting Tucson, Arizona.